Foam Technologies

Foam Suppliers Perth

Australia’s leading EPS Foam and Polystyrene foam suppliers & manufacturers servicing the building and construction sector.

EPS Foam and Polystyrene Foam Products Suppliers Perth

Foam Insulation Sheets – Polystyrene Sheets and Boards

Foam Insulation Sheets – Polystyrene Sheets and Boards

Polystyrene sheets is a closed cell, lightweight rigid cellular plastic material produced in a range of densities from 13.5kg/m3 and 28 kg/m3 which offers excellent thermal insulation properties. They can be cut into all shapes and sizes or profiled using computer hotwire cut CNC cutting processes. Polystyrene insulation is used across various industries, including civil engineering, construction, packaging applications. It is valued for its durability, ease of handling, and high strength to weight ratios including shock absorbing characteristics.

Foam Insulation Panels - EPS Polystyrene Boards - Polystyrene Sheets

Foam insulation panels and boards are known for their its excellent thermal insulating properties. Polystyrene sheet applications include thermal insulation systems for all areas of building construction, walls, roofs and sub-floors. Foam board panels can be used for ceiling, decorative surfaces, protective packaging, display boards, signage, letters, models, props and stage sets for trade shows.

Foam Technologies stock a range of densities of polystyrene sheets and foam insulation boards (Standard) SL, (Medium) M, and (Hard) H, and VH grades). Standard sheet sizes are 2400x1200mm and 3600x1200mm which can be cut to thickness from 10mm to 600mm. Special custom cut sheet sizes can be ordered with quick turn-around times.

Physical Properties

Density:

- Standard Range: 13.5 kg/m3 -28 kg/m³

Thermal Conductivity:

- Range: 0.032 - 0.044 W/m·K

Compressive Strength:

- Range: 70 – 165 KPA

Water Absorption:

- Typical Value: 2-4% by volume

- Polystyrene have minimal water absorption, which contributes to their durability and effectiveness.

Dimensional Stability:

- Temperature Range: -50°C to 75°C

- Foam boards can maintain their shape and performance across a wide range of temperatures, making them suitable for various environmental conditions.

Applications of Foam Insulation Sheets

Construction

Insulation: Polystyrene sheets and foam insulation sheets and insulation boards are used as thermal insulation in cavity walls, external wall cladding systems, insulated panels for roofs, under slab or underfloor insulation. The excellent insulating properties help reduce heat gain or heat loss saving energy and reducing energy consumption.

Lightweight Fill Material: Ideal for use as lightweight infill void foam for landscaping, weight reduction, soil stabilisation for retaining walls and roof top gardens.

Packaging

Protective Packaging: Polystyrene are used to protect sensitive and fragile items during shipping. Their cushioning properties help to absorb shocks and impacts.

Marine and Buoyancy

Floating Devices: Foam board is utilised in the construction of floating devices such as buoys and marine applications due to their buoyant properties.

Arts and Crafts

Model Making: The ease of cutting and shaping polystyrene sheets makes them a popular choice for creating scale models, prototypes, and artistic installations.

Geotechnical Engineering

Lightweight Fill: Used in geotechnical applications to reduce the load on underlying soils and structures, especially in areas with weak ground conditions.

Environmental Considerations

Recyclability

Foam Insulation boards are recyclable. It can be processed into other materials, helping to reduce waste.

Handling and Safety

Handling

Handle foam board insulation sheets carefully to avoid damage. Use proper lifting techniques to manage their weight and size and protect the blocks from impacts that could cause deformation.

Safety Precautions

When cutting or shaping polystyrene boards sheets, use protective gear such as gloves and masks to avoid inhaling dust or debris.

Storage

Store polystyrene in a dry, cool location away from direct sunlight and chemicals that could degrade the material.

Quality Assurance

Polystyrene Insulation boards and sheets conform to the relevant industry standards and building codes. Regular testing for density, thermal conductivity, and compressive strength to ensures consistent product quality and performance across all product categories.

Polystyrene Wall Cladding

Polystyrene Wall Cladding

Expanded polystyrene wall cladding is known for its excellent insulation properties and has become increasingly popular in modern construction. Due to its unique properties, expanded polystyrene (EPS) insulation boards are ideal for external insulation applications. Polystyrene cladding systems typically consist of several layers, 75 mm thick EPS insulation board, a base coat, reinforcement mesh, and a finish coat, designed to provide thermal insulation, enhance aesthetic appeal, and protect the building structure from external elements.

Benefits of Expanded Polystyrene Cladding

Superior Insulation

Polystyrene wall cladding provides excellent thermal insulation, reducing heat loss in winter and heat gain in summer. This results in significant energy savings and enhanced indoor comfort.

Lightweight

Polystyrene insulation boards are lightweight, making it easy to handle and install. This reduces construction time and labour costs.

Design Flexibility

The use of Polystyrene insulation boards offers a wide range of design options, including various textures, colours, and finishes. It can be customised to match the appearance of other materials such as brick, stone, or wood.

Durability

When properly installed and maintained, polystyrene insulation systems are highly durable and resistant to weathering, impact, and moisture.

Cost-Effective

The cost of materials and installation for polystyrene insulation sheets is generally lower than traditional cladding materials like brick or stone. The energy savings over time further enhance its cost-effectiveness.

Applications of Polystyrene Wall Cladding

Residential Buildings

Expanded polystyrene cladding is widely used in residential construction for both new builds and renovations. It provides excellent insulation and aesthetic versatility.

Retrofitting

Older buildings can benefit from the energy efficiency and aesthetic upgrades provided by polystyrene insulation boards. Retrofitting with EPS cladding can significantly enhance the building's performance and curb appeal.

Wall Cladding Installation Process

1. Preparation: The building surface must be clean, dry free of debris. Any necessary repairs to the substrate should be completed before installation.

2. Application of Insulation Boards: EPS insulation boards are cut to size and adhered to the building surface using an adhesive mortar. The boards are then mechanically fastened for additional security.

3. Base Coat and Reinforcement: A base coat is applied over the insulation boards, followed by embedding a fiberglass mesh for reinforcement. This layer provides strength and resistance to cracking.

4. Finish Coat: A finish coat is applied to provide the desired texture and colour. This layer protects the insulation and enhances the building's appearance.

EPS polystyrene cladding offers a modern, versatile, and cost-effective solution for insulating and enhancing the exterior of buildings. Its benefits in terms of energy efficiency, design flexibility, ease of installation make it an attractive option for both residential and commercial projects.

Custom Profile Cut Computer Shapes

Custom Profile Cut Computer Shapes

Foam Cutting

EPS (Expanded Polystyrene Sheets) or blocks can be cut into all shapes and sizes or profiled using computer hotwire CNC cutting processes for a variety of profiled shapes from protective packaging, to display boards, trade signage, letters, models, props, stage sets etc. Foam Technologies provides inhouse design assistance and custom foam cutting for Bespoke solutions for Infrastructure formwork, mould pattern making, to customised packaging.

EPS foam can be custom cut into specific designs and patterns using computer-controlled machinery. The process involves using CAD software to design the desired shapes, which are then executed by CNC cutting machines. This allows for highly intricate and accurate cut shapes that can be used in various applications.

Developing Your Concept

A member of our Project Design Team will work with you to develop your concept. We provide a full design service to support your in-house capabilities: 2D/3D CAD applications, material selection, prototyping and mock-up samples.

Benefits of Custom Foam Cutting

Precision and Accuracy

The use of CAD and CNC technology ensures that EPS profile cut shapes are produced with a high degree of precision and accuracy. This is especially important for architectural elements and signage where consistency is key.

Design Flexibility

EPS foam can be custom cut into virtually any shape or size, offering unparalleled design flexibility. Whether it’s a complex cornice design or a custom logo, EPS profile cutting can bring any vision to life.

Lightweight and Durable

EPS Expanded Polystyrene foam is incredibly lightweight, making it easy to handle, transport, and install. Despite its lightweight, it is also durable, which can be further enhanced with our hard-coating process.

Cost-Effective

Compared to traditional materials like wood or stone, EPS foam is more cost-effective.

Sustainability

EPS is recyclable, and advancements in manufacturing have made it more environmentally friendly. The precision cutting process also minimises waste, contributing to more sustainable production practices

Applications of Foam Cut Shapes & Sizes

Architectural Elements

EPS - profile cut Polystyrene shapes are widely used to create architectural elements such as columns, cornices, moldings and architraves. These elements can enhance the aesthetic appeal of buildings, both residential and commercial, while being lightweight and easy to install.

Themes and Scenography

In the entertainment industry, EPS profile cut shapes are used for creating props, sets, and themed environments.

Signage and Branding

EPS profile cut shapes are popular in the signage industry for creating three-dimensional signs and logos. Their lightweight nature makes them easy to mount.

Insulation and Packaging

Foam cutting plays a crucial role in insulation and packaging. Custom cut EPS forms can provide superior thermal insulation and protect delicate items during shipping.

Architectural Renovations

Many historical buildings undergoing renovations use EPS profile cut shapes to replicate intricate architectural details that would be costly and time-consuming to produce with traditional materials. This approach preserves the building's historical integrity while reducing renovation costs.

Retail and Commercial Spaces

Retail stores and commercial buildings often utilise EPS profile cut shapes and letters for branding and signage.

Custom foam cutting has revolutionised design, offering unparalleled precision, flexibility, and cost-effectiveness. From detailed architectural facades to intricate props, EPS allows for greater creativity for designers and builders.

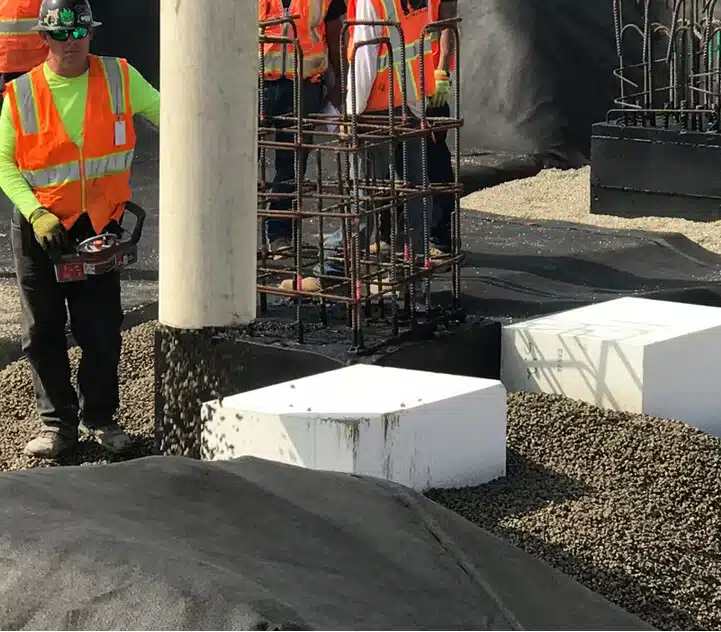

Construction Foam Blocks – Polystyrene Void Formers

Construction Foam Blocks – Polystyrene Void Formers

Concrete Foam

Concrete foam blocks (also known as polystyrene void formers) are an integral component in construction and civil engineering applications. Isolite - Polystyrene void formers are lightweight, rigid foam profiles or blocks cut to size made from expanded polystyrene (EPS) resulting in a material that is both durable and lightweight.

Applications for Using Concrete Construction Foam Blocks

The void formers are used in concrete construction to create gaps or voids within structures. Concrete foam is often necessary in concrete to form a void or space for utilities or services such as pipework junctions within a manhole or block-outs in a concrete mould. The use of construction foam blocks or block-outs in precast concrete applications allow for faster turn-around times, the length or shape of an existing mould can be quickly adjusted reducing overall fabrication cost and increasing productivity.

Building Foundations

In foundation construction, Concrete foam blocks are used to create space for utilities or to reduce the weight of the foundation.

Floor and coffered slabs

In commercial buildings or parking structures, void formers can reduce the amount of concrete needed while maintaining structural integrity. This is particularly beneficial in high-rise buildings where weight considerations are crucial.

Retaining Walls

In retaining wall construction, sacrificial void formers can be used to create cavities within the retaining wall construction when removed, providing the opening or cavity required for drainage. Void infill blocks can be used to stabilise soils that reduce the load enhancing the stability and longevity of the retaining system.

Bridge Decks

(EPS), Void Formers provide significant benefits in terms of weight reduction, cost efficiency, and structural integrity. Engineers can optimise and enhance the performance and cost-efficiency of concrete bridge structures using Foam Tech Iso-lite foam profiles that are cast in-situ, resulting in less concrete being required. The reduction in weight decreases the load on supporting structures and foundations leading to improved overall stability and reduced structural demands.

Benefits of Using Construction Foam Blocks -

Weight Reduction

One of the primary advantages of using Polystyrene void formers is the reduction in the overall weight of the concrete structure. By creating voids, the weight of the concrete slab is significantly reduced. This reduction can decrease the load on supporting beams and foundations, leading to cost savings in structural supports and materials.

Cost Efficiency

The use of Polystyrene EPS foam can lead to substantial savings in large-scale construction projects by reducing the amount of concrete required for a project.

Improved Thermal Insulation

Polystyrene has excellent insulating properties. When EPS void formers are used in construction to insulate a concrete slab they can contribute to increasing the energy efficiency within the structure. This enhances the overall thermal performance reducing heating and cooling costs over the lifespan of the building.

Ease of Handling

Construction foam blocks or void formers are lightweight and easy to handle, which simplifies the construction process. They are easy to cut and shape on-site, allowing for quick adjustments and installation.

Environmental Benefits

By using Polystyrene void formers, construction projects can become more environmentally friendly. Reduced concrete usage lowers the carbon footprint associated with cement production, and the insulation properties of EPS can contribute to energy savings.

Construction Foam Blocks in Perth

Construction foam blocks offer a range of benefits that make them a valuable tool in modern construction. From reducing weight and construction costs to enhancing thermal insulation, these innovative materials contribute to more efficient and sustainable building practices. Whether used in foundations, floor slabs, retaining walls, or bridge decks, construction foam plays a crucial role in optimising concrete structures and improving the overall quality of construction projects. As the industry continues to seek out more cost-effective and environmentally friendly solutions, EPS construction is poised to remain an essential component in the future of the building industry.

Pipe Insulation

Pipe Insulation

Expanded Polystyrene (EPS) foam insulation for (pipe insulation) is a versatile and effective solution for insulating chilled water pipework in commercial and industrial applications. Pre-cut insulation segments are cut from EPS (Expanded Polystyrene Block) using computer hotwire CNC cutting processes. The use of CNC technology ensures that pipe sections are cut precisely to meet exacting tolerances. The pre-formed sections are supplied in two halves so they can be easily fitted as lagging around chilled water pipework to suit a range of pipe diameters. EPS pipe insulation sections are manufactured from a rigid, closed-cell Polystyrene foam, renowned for its excellent thermal insulating properties.

Applications of Foam Insulation

Cold Water Pipes

Foam insulation is commonly used to insulate cold water pipes in plant rooms and pipe work in industrial applications to prevent condensation on chilled water pipes, improving thermal efficiency and preventing moisture-related issues.

HVAC Systems

Insulating HVAC ductwork and piping with EPS helps maintain the desired temperature of air and fluids, thus enhancing the efficiency of heating and cooling systems.

Process Piping

EPS Pipe insulation lagging is used to insulate process pipework in industrial and commercial facilities, maintaining the temperature of fluids and gases as they travel through the pipework system. This is crucial for processes that require precise temperature control.

Refrigeration and Cold Storage

In refrigeration systems and cold storage facilities, EPS pipe insulation helps maintain temperatures and prevents condensation on pipes, ensuring optimal performance and energy efficiency.

Benefits of EPS Foam Insulation

Reduced Energy Consumption

The use of EPS pipe insulation lowers energy consumption resulting in cost savings on the running costs of plant and equipment.

Environmental Impact

Lower energy consumption translates to reduced greenhouse gas emissions, contributing to a more sustainable and eco-friendly building environment.

Ease of Installation

EPS pipe insulation is lightweight and therefore easy to apply. EPS pipe foam insulation is available in pre-formed, split sections that can be quickly fitted and secured around pipes, simplifying the installation process.

Cost - Effectiveness

EPS insulation is a cost-effective insulation material compared to alternatives such as fiberglass or polyurethane foam. Its affordability makes it an attractive option for a wide range of applications. The durability and moisture resistance of EPS insulation reduces the need for maintenance and repairs, leading to long-term cost savings. EPS can be easily customised to fit pipes of various diameters and lengths, ensuring a perfect fit and optimal insulation performance.

Installation Guidelines

- Measure and cut the foam pipe sections to the required length using standard cutting tools. Pre-formed, split sections should be used for a precise fit around the pipes.

- The split sections should be aligned and sealed to prevent thermal bridging.

- Seal any joints or gaps between the insulation sections with suitable sealant or tape to ensure a continuous thermal barrier and prevent heat gain or heat loss.

- Protective vapor barriers/coatings or cladding over the EPS pipe insulation to enhance its durability and resistance is recommended for most insulation applications.

EPS Pipe Insulation stands out as a practical and effective option for new installations or retrofitting existing systems. EPS insulation provides a reliable and long-lasting solution that contributes to the overall performance and sustainability of the building.

Geofoam Blocks

Geofoam Blocks

Stabilising sloping ground EPS Geofoam blocks are the ideal solution because its 50 times lighter than conventional fill materials, providing an alternative method to reinforce soil embankments or deal with challenging Geotechnical issues on site. Geofoam used in higher density grades supplied by Foam Technologies can be used as a base for road or rail embankments where traditional fill materials are too heavy.

Geofoam block is the preferred fill material to replace dirt and soil because its lightweight, easy to transport, handle and install. Traditional fills would require multiple truck loads of material, adding considerable load to the substrate below. Geofoam provides a stable fill with excellent load bearing performance characteristics.

What is EPS geofoam?

EPS Geofoam used in geotechnical applications, is a lightweight block fill material used to reduce load strain, for Civil Engineering projects such as roads, railways, stadiums and bridge abutment.

Geofoam is typically made from expanded polystyrene (EPS). EPS is a versatile building material that’s easy to work with and offers several performance advantages.

Where is geofoam used in Perth?

You’ll find EPS geofoam used in any number of construction applications. Engineers, architects and builders use the material to stabilise and reinforce foundations ranging from developments to large-scale public infrastructure:

- Rooftop gardens

- Retaining walls

- Stabilising soft soils

- Tiered stadium seating

- Road embankments

- Bridge abutment and underfill

- Protecting buried services

- Railway embankments

The benefits of using EPS geofoam in Perth construction projects

Saves time

Perhaps the most significant benefit of EPS geofoam is the time it saves on civil engineering and construction projects.

Easy to install

EPS geofoam is light weight and easy to install without specialised equipment. Geofoam blocks can easily be trimmed on site or customised to suit the application.

Lightweight

Geofoam has a density of 15-22 kg/m3, around 1% that of soil or rock. So it’s an ideal solution for rooftop gardens, soft soil stabilisation, and other applications where the added load would cause stress on underlying subgrades.

Structurally strong and durable

EPS blocks can be supplied in a range of densities offering excellent compressive strength and load-bearing characteristics without adding significant weight to the sub-structure.

Versatile

Geofoam is produced in blocks that can be cut, shaped and combined to create unique architectural and design solutions.

This enables engineers, architects and builders to design by function; that is, choose the best materials for the project goals rather than being restricted by what’s available.

Geotechnical Engineers have long recognized the usefulness of light weight fill to reduce load strain. EPS Geofoam is a perfect fit, giving designers a unique product that works in conjunction with other traditional materials to solve construction problems with unprecedented strength and flexibility.

Weather resistant

EPS geofoam has low moisture absorption rates.

Inert and non-toxic

EPS foam blocks are non-toxic and chemically inert. They offer no nutrients for vermin, won’t leach chemicals into nearby waterways, and can be easily treated to repel insects.

In addition, EPS geofoam doesn’t contain HFCs or HCFCs, is carbon-negative, and assists in reaching 6-Star energy efficiency ratings.

EPS geofoam is also 100% recyclable. We reclaim all off-cuts and reprocess them into raw material for other projects.

When it comes down to it, EPS geofoam is a lightweight fill material beyond compare. It’s versatile, easy to use, strong, and reliable without adding weight to underlying structures or interfering with local ecology.

Foam Technologies is a foam supplier in Perth and offer the best EPS geofoam solutions in Western Australia. From standard blocks to highly customised solutions, we can meet your specific project needs with the best material in the business.

Underfloor Insulation Sheets

Underfloor Insulation Sheets

Expanded Polystyrene (EPS) is a rigid, lightweight, and durable foam insulation sheet which offers homeowners a quick and simple solution for retrofitting existing floor systems. EPS underfloor insulation involves the installation of EPS foam sheets beneath the flooring system to create a thermal barrier. This barrier helps maintain a more constant indoor air temperature by preventing heat loss during the winter and minimising heat gain during the summer.

Benefits of Foam Insulation Sheets

Thermal Efficiency

In winter, underfloor foam insulation sheets significantly reduce heat loss through the floor, keeping indoor spaces warmer. This contributes to a more comfortable living environment and reduces the need for heating.

In summer, underfloor insulation sheets help keep the air temperature cooler inside, reducing the load on air conditioning systems and maintaining a comfortable indoor temperature.

Energy Savings and Environmental Impacts

By improving the thermal performance of the building envelope, EPS insulation sheets reduce the need for heating and cooling, leading to lower energy consumption. This translates to cost savings on energy bills. Lower energy consumption means reduced greenhouse gas emissions, contributing to a more sustainable and eco-friendly home.

Ease of Installation of Sheets

Lightweight and Easy to Handle

EPS insulation sheets are lightweight and easy to cut, making them simple to install. The external edges of the EPS sheets are concertina cut so they can compress and fit snugly between timber floor joists. This reduces labour costs and installation time.

Versatility

Standard EPS insulation sheets and panels are available in a range of widths to suit most floor joists from 410 mm, 470 mm & 560 mm. Custom widths are also available for special orders.

Moisture Resistant

Foam insulation sheets are inherently resistant to water absorption, preventing moisture-related issues such as mold growth and structural damage. This makes it an excellent choice for underfloor applications where moisture may be a concern.

Installation Guidelines for Insulation Sheets

Site Preparation:

- Ensure the floor area is clean, dry and free of debris.

- Perform a site assessment to determine joists measurements for the required insulation width.

Cutting and Fitting:

- Measure and cut EPS sheets to fit the specific dimensions of the floor area.

- Lay the EPS sheets snugly together, ensuring no gaps between them.

Securing the Insulation:

- Use appropriate mechanical fixings where necessary to secure the EPS sheets in place.

- Seal any gaps or joints to prevent thermal bridging.

Vapor Barrier (if required):

- Install a vapor barrier over the EPS insulation to enhance moisture resistance.

Safety Information

- Foam insulation sheets are non-toxic and safe to handle.

- Use appropriate personal protective equipment (PPE) such as gloves and masks during installation.

- Follow local building codes and regulations regarding fire safety and insulation installation.

Foam insulation sheets offer a multitude of benefits that enhance both the energy efficiency and comfort of buildings. Its excellent thermal performance, cost-effectiveness, durability, and ease of installation make it an ideal choice for a wide range of applications. By investing in foam insulation sheets, homeowners and builders can achieve significant energy savings, improved indoor comfort, and a reduced environmental footprint.

Technical Specifications

| Material: | Expanded Polystyrene (EPS) |

| Density: | 13.5-28 kg/m³ |

| Thermal Conductivity: | 0.033 - 0.038 W/mK |

| Compressive Strength: | 75 - 165 kPa |

| Water Absorption: | < 2% (by volume) |

| Fire Resistance: | Fire retardant |

| Dimensional Stability: | Excellent |

| Environmental Impact: | 100% recyclable |

Product Range

|

Product Code |

Thickness (mm) |

Dimensions (mm) |

R-Value |

|

EPS-410 |

60 | 1200 x 410 | 1.5 m²K/W |

|

EPS-470 |

60 |

1200 x 470 |

1.5 m²K/W |

|

EPS-560 |

60 |

1200 x 560 |

1.5 m²K/W |

Polymoulds – Hardcoat Finishes

Polymoulds – Hardcoat Finishes

Polymoulds can be computer cut using specialised CNC equipment to achieve attractive shapes for concrete casting in relief. Polyurethane hard coat finishes applied to the mould allow multiple castings to be achieved ensuring continuity in shape and finish. Contact us for Hardcoat Finishes Polymoulds in Perth

Feature Moulds

Feature Moulds

Foam Technologies offers Bespoke solutions for custom-designed moulds, to create decorative architectural elements, infrastructure formwork and mould pattern making. Foam Moulds can be precisely cut into specific designs and patterns using computer-controlled CNC machinery. The process involves using CAD software to design the desired shapes, which are then executed by CNC cutting machines. This allows for highly intricate and accurate mould shapes that can be used in various casting applications.

Develop Your Concept With Custom EPS Mouldings

A member of our Project Design Team will work with you to develop your concept. We provide a full design service to support your in-house capabilities: 2D/3D CAD applications, material selection, prototyping and mock-up samples.

Benefits of Custom EPS Moulding - CNC cut Moulds

Precision and Accuracy

The use of CAD and CNC technology ensures that EPS moulds are produced with a high degree of precision and accuracy. This is especially important for architectural elements.

Design Flexibility

EPS foam can be cut into virtually any shape or size, offering unparalleled design flexibility. Whether it’s a complex cornice design or a custom logo, EPS profile cutting can bring any vision to life.

Cost-Effective

Compared to traditional materials, EPS foam is more cost-effective for manufacturing sacrificial moulds, prototyping new product concepts or casting one off decorative forms in concrete

Durability

EPS moulds can be finished with various coating processes such as epoxy resin, fibreglass, Polyurethane elastomer (hard coating) to suit your application.

Prefabrication

Many architectural features can be pre-fabricated off-site and then transported to the construction site, speeding up the project timeline.

Applications of EPS Architectural Feature Moulds

Restoration and Preservation

Historical Buildings

Architectural feature moulds are invaluable in the restoration and preservation of historical buildings. They enable the accurate replication of original details that may have been damaged or eroded over time.

Authenticity

Using moulds to recreate historical elements ensures that renovations maintain the authenticity and integrity of the original design.

Residential Architecture

Exterior Enhancements

External features like cornices, window trims, and decorative columns can transform the facade of residential or commercial buildings, increasing its curb appeal and market value.

EPS Architectural mouldings feature moulds have revolutionised the way intricate design elements are incorporated into buildings and have made them an essential tool in modern architecture and restoration projects.

From enhancing residential interiors to restoring historical landmarks, architectural feature moulds manufactured in EPS foam offer endless possibilities for creating visually stunning buildings. By leveraging these moulds, architects and designers can continue to push the boundaries of creativity and innovation in the built environment.

Polystyrene Packaging – Packing Foam

Polystyrene Packaging – Packing Foam

EPS (Expanded Polystyrene Sheets) or blocks can be cut into all shapes and sizes or profiled using computer hotwire CNC cutting processes for a variety of profiled shapes for protective packing foam. Foam Technologies provides inhouse design assistance for Bespoke solutions for customised packaging.

EPS foam can be precisely cut into specific designs and patterns using computer-controlled machinery. The process involves using CAD software to design the desired shapes, which are then executed by CNC cutting machines. This allows for highly intricate and accurate shapes that can be used in packaging.

Developing Your Concept For Packing Design

A member of our Project Design Team will work with you to develop your concept. We provide a full design service to support your in-house capabilities: 2D/3D CAD applications, material selection, prototyping and mock-up samples.

Benefits of EPS Packing Foam

Precision and Accuracy

The use of CAD and CNC technology ensures that EPS profile cut shapes are produced with a high degree of precision and accuracy.

Design Flexibility

EPS can be cut into virtually any shape or size, offering unparalleled design flexibility for packing foam.

Lightweight and Durable

EPS foam is incredibly lightweight, with excellent shock absorbing properties. Custom-cut EPS packing foam protects delicate items during shipping.

Sustainability

EPS is recyclable, and advancements in manufacturing have made it more environmentally friendly. The precision cutting process also minimises waste, contributing to more sustainable production practices

Applications of EPS Profiled Packing Foam

Insulation and Packaging

EPS profile cut shapes play a crucial role in insulation and packaging. Custom-cut EPS packing foam can provide superior thermal insulation and protect delicate items during shipping. Expanded Polystyrene (EPS) has become a vital material in the packaging industry due to its unique properties and versatility. EPS packing foam provides reliable protection for a wide range of products, from delicate electronics to perishable food items.

Temperature-Sensitive Products

EPS packing foam is essential for the safe transportation of temperature-sensitive medical supplies and pharmaceuticals, including vaccines, insulin, and biological samples. The insulation properties of EPS ensure that these items remain within the required temperature range.

Letters, Signage and Trade displays

Letters, Signage and Trade displays

Polystyrene foam letters and signage are a versatile solution for eye-catching and effective displays. Expanded Polystyrene (EPS) letters are created using expanded polystyrene foam, a lightweight and durable material. These properties, combined with the ability to be precisely cut into various shapes and designs using computer-aided design (CAD) and computer numerical control (CNC) machinery, make EPS an ideal material for custom signage and lettering.

The Process of Creating EPS Foam Letters and Signage

Design Phase

The process begins with designing the letters or signage using CAD software. This allows for precise customisation in terms of size, font, and style. Clients can visualise the design before production, ensuring it meets their specifications.

Cutting EPS Foam

The CNC machine uses hot wire cutting processes to produce the foam letters and signage. These methods ensure high precision and smooth edges, creating a professional and polished appearance.

Finishing Touches

After cutting, the EPS letters and signage can be painted, coated, or laminated with various materials to achieve the desired finish. This step allows for endless customisation options to match brand colours and themes.

Applications of Foam Letters and Signage

Trade Shows and Exhibitions

Booth Signage

Foam letters are commonly used to create large, striking booth signage that draws attention from across the exhibition hall. Their lightweight nature makes them easy to transport and install, while their durability ensures they can be reused for multiple events.

3D Logos and Branding

Companies often use EPS to create three-dimensional logos and branding elements. These can be prominently displayed at trade shows, helping businesses stand out and create a memorable impression.

Retail and Commercial Spaces

Storefront Signage

Foam letters and signage are perfect for storefronts, providing an attractive and professional look. They can be customised to fit any branding.

Interior Displays

Inside retail spaces, EPS foam letters can be used for product displays, promotional messages, and directional signage. Their versatility allows for creative and dynamic interior design solutions.

Events and Promotions

Event Signage

For events such as weddings, corporate functions, and parties, foam letters can be used to create customised signage that enhances the venue’s décor. From large monograms to themed decorations, EPS offers endless possibilities.

Promotional Campaigns

During promotional campaigns, EPS foam letters and signage can be used for pop-up installations, point-of-sale displays, to enhance other marketing efforts. Their cost-effectiveness makes them an ideal choice for short-term promotions.

Benefits of EPS Foam Letters and Signage

Lightweight and Easy to Handle

EPS is extremely lightweight, making it easy to transport, install, and reposition. This is especially beneficial for trade shows and events where quick setup and teardown are essential.

Cost-Effective

Compared to materials like metal, wood, or acrylic, EPS is more affordable. This cost efficiency makes it an attractive option for businesses of all sizes, particularly for temporary installations and promotions.

Customisable and Versatile

EPS can be cut into any shape, size, or design, offering unparalleled customisation options. Whether it’s intricate logos or large block letters, EPS can meet diverse design needs.

Foam letters and signage can be finished with various coatings and paints to achieve a high-quality, professional look. This includes metallic finishes, glossy paints, and textured coatings, allowing for a wide range of aesthetic options.

Eco-Friendly Options

EPS is recyclable, the production of Foam letters and signage generates minimal waste, contributing to more sustainable practices in the signage industry.

Foam letters and signage have revolutionised the way businesses create impactful trade displays and branding elements. Their light weight and customisable nature make them an ideal choice for various applications, from trade shows and retail spaces to corporate events and promotional campaigns. By leveraging the unique properties of EPS, businesses can create visually stunning displays that capture attention and leave a lasting impression.

Materials – Polystyrene Foam Blocks

Materials – Polystyrene Foam Blocks

Expanded polystyrene foam blocks is a closed cell, lightweight rigid cellular plastic material, produced in a range of densities from 13.5 kg/m3 and 28 kg/m3 which offers excellent thermal insulation properties. Closed cell foam is used across various industries including civil engineering, construction and packaging applications, as it is valued for its durability, ease of handling, and high strength to weight ratios including shock absorbing characteristics.

Closed Cell Foam Blocks

EPS polystyrene foam blocks are renowned for their excellent thermal insulating properties and are an economical solution for landscaping applications, when used as void infill material for planter box or concrete formwork, voids and block outs, pipe insulation, pontoons, floatation and buoyancy applications.

Foam Technologies stock a range of closed cell block densities, (Standard) SL, (Medium) M, and (Hard) H, and VH grades). Standard sheet sizes are 2400x1200mm and 3600x1200mm which can be cut to thickness from 10mm to 600mm. Special custom block and cut sheet sizes can be ordered with quick turn-around times.

Physical Properties of Foam Block

Density:

• Standard Range: 13.5 kg/m3 -28 kg/m³

Thermal Conductivity:

• Range: 0.032 - 0.044 W/m·K

Compressive Strength:

• Range: 70 – 165 KPA

Water Absorption:

• Typical Value: 2-4% by volume

• EPS polystyrene blocks have minimal water absorption, which contributes to their durability and effectiveness.

Dimensional Stability:

• Temperature Range: -50°C to 75°C

• Closed cell foam maintains their shape and performance across a wide range of temperatures, making them suitable for various environmental conditions.

Applications Of EPS Polystyrene Foam Blocks

Construction

Insulation: EPS polystyrene blocks can be cut into sheets to be and used as thermal insulation in cavity walls, external cladding systems, insulated panels for roofs, under slab or underfloor insulation. The excellent insulating properties help reduce heat gain or heat loss saving energy and reducing energy consumption.

Lightweight Fill Material: Ideal for use as lightweight infill applications such as void foam for landscaping, weight reduction, soil stabilisation for retaining walls and roof top gardens.

Packaging

Protective Packaging: EPS polystyrene foam blocks and sheets are used to protect sensitive and fragile items during shipping. Their cushioning properties help to absorb shocks and impacts.

Marine and Buoyancy

Floating Devices: Polystyrene foam blocks are utilised in the construction of floating devices such as buoys and marine applications due to their buoyant properties.

Arts and Crafts

Model Making: The ease of cutting and shaping polystyrene blocks makes them a popular choice for creating scale models, prototypes, and artistic installations.

Geotechnical Engineering

Lightweight Fill: Used in geotechnical applications to reduce the load on underlying soils and structures, especially in areas with weak ground conditions.

Environmental Considerations

Recyclability

EPS polystyrene foam blocks are recyclable. They can be processed into other materials, helping to reduce waste.

Handling and Safety

Handling

Handle polystyrene foam blocks carefully to avoid damage. Use proper lifting techniques to manage the size and weight. Protect the blocks from impacts that could cause deformation.

Safety Precautions

When cutting or shaping EPS polystyrene foam blocks, use protective gear such as gloves and masks to avoid inhaling dust or debris.

Storage

Store polystyrene blocks in a dry, cool location away from direct sunlight and chemicals that could degrade the material.

Quality Assurance

EPS polystyrene foam blocks conform to the relevant industry standards and building codes. Regularly testing for density, thermal conductivity, and compressive strength properties ensure consistent product quality and performance.

Recycled EPS

Recycled EPS

Foam Technologies recycles all off-cuts and unused recycled EPS in Perth which can be easily re-processed and combined with other plastic materials to simulate wood mouldings, or extruded forms such as picture frames, garden seats and fence posts.

Contact Us for Recycled EPS in Perth

Welcome to

Foam Technologies – Foam Suppliers Perth

Foam Technologies is a leading Perth foam manufacturer and supplier. We provide EPS computer cut polystyrene profiles, void infill-foam, EPS foam blocks, Polystyrene insulation sheets and architectural mouldings for the building Industry.

Polystyrene Foam Manufacturer And Supplier in Perth

Through growth and diversification, Foam Technologies has become an industry leader in manufacturing and supplying customised polystyrene formwork. We specialise in the production of 2D and 3D foam moulds, including displays, lettering, feature moulds and signage. Foam Technologies offers polyurethane hard coated finishes, which can be applied to polystyrene foam, timber, steel, and other substrates to provide a tough, abrasion-resistant shell coating. The shell coating is tough, wear & scuff-resistant and able to withstand the rigours of sharp knocks and bangs associated with formwork applications in the precast concrete industry. Contact us today to find out more about our foam solutions.

WHY CHOOSE FOAM TECHNOLOGIES FOR POLYSTYRENE FOAM IN PERTH

Foam Technologies is an established foam supplier in Perth, working to provide high-quality polystyrene foam solutions to businesses. Offering quick turnaround times, superior service, and a commitment to quality, Foam Technologies is the ideal partner for businesses seeking reliable, energy-efficient, and cost-effective foam products, whether it’s for construction, packaging, or your insulation requirements.

Cost Effective

Moisture Resistant

Light Weight

Energy Efficient

Durable

Thermally Efficient

Recyclable

Polystyrene FoAM Work in Perth

Geofoam Blocks

Work Type

Car Parking Development - Darwin

Product Used

Geofoam

The redevelopment of a public space, once an open car park in Darwin’s CBD, is turned into a lush green landscaped area for public use, using Geofoam Blocks supplied

Enquire Now

Bridge Deck Void Formers

Work Type

Bridge Deck Construction

Product Used

Expanded Polystyrene (EPS)

Polystyrene void formers are an innovative solution in bridge deck construction design. Void formers made from Expanded Polystyrene (EPS), provide significant benefits

Enquire Now

Port Coogee Slab

Work Type

Curved Landscape

Product Used

Polystyrene Geofoam blocks

Nine large concrete panels were designed and constructed as a landscape feature forming part of the walkway that was installed in the Port Coogee, marina. The decorative

Enquire Now

Karrinyup Shopping Centre

Work Type

Curved Landscape

Product Used

Polystyrene Geofoam blocks

The recent renovations at the hugely popular shopping centre in Karrinyup included a complete re-vamp of the food and entertainment precinct. Beautifully landscaped

Enquire Now

Crown Plantroom

Work Type

Curved Landscape

Product Used

Pre-cut Polystyrene

Pre-cut Polystyrene pipe insulation was used to insulate Crowns Casino’s Plantroom in Burswood. Chilled water pipework that services the air conditioning system was

Enquire Now

Jutland Parade

Work Type

Curved Landscape

Product Used

Polystyrene Geofoam blocks

Channel 7 owner, Kerry Stokes builds a new house on Jutland Parade in Dalkeith. A large triangular shaped concrete balcony forms part of the roof top garden feature

Enquire Now

Perth Children’s Hospital

Work Type

Curved Landscape

Product Used

Polystyrene Geofoam blocks

Foam Technologies created a high-functioning landscape feature with a visually pleasing finish for The Perth Children’s Hospital Project. The aesthetic curved design

Enquire Now

285 West Coast Highway – Apartments

Work Type

Curved Landscape

Product Used

Polystyrene Geofoam blocks

The unique exterior architectural feature at the 285 West Coast Highway Apartment buildings in Scarborough, Perth, is a fantastic example of the versatility of expanded

Enquire NowLatest FOAM TECHNOLOGIES News

Foam Cladding vs Brick: Which Rendered Foam Insulation Option is Right for Your Home?

Jul 3, 2023

Insulating your home is a significant decision that affects energy efficiency, comfort, and cost-effectiveness. Today,...

The Wonders of Geofoam: Revolutionising Highway Construction

Jun 30, 2023

Geofoam, a lightweight, cost-effective, and environmentally-friendly construction material, has transformed highway...

Where Is Expanded Polystyrene (EPS) Foam Found In Perth?

Feb 13, 2023

Expanded polystyrene foam, better known as EPS foam, is a versatile material used in all corners of Perth’s...